Inspecting high-risk environments requires tools that combine precision, reliability, and safety. From aviation engines to chemical processing equipment, many critical systems hide potential faults inside tight, dark, and hazardous spaces. An ultra-thin borescope gives technicians the ability to see inside these areas without dismantling equipment or exposing themselves to unnecessary danger. Its slim profile, advanced optics, and rugged design make it a standout choice wherever conditions are harsh and margin for error is small.

Reaching Critical Areas Without Disassembly

In high-risk environments, shutting down equipment for full disassembly is often costly and sometimes impractical. Ultra-thin borescopes are designed to access tiny openings, narrow channels, and complex internal pathways while the main structure stays intact.

Instead of removing large components, a technician can insert the borescope through an existing port, vent, or bolt hole and guide the camera directly to the area of concern. This approach reduces downtime, maintains system integrity, and allows rapid checks after alarms, unusual vibrations, or temperature spikes. Over time, it supports a more proactive maintenance culture, where problems are identified early rather than after a failure.

Precision Imaging in Tight Spaces

In high-risk environments, seeing clearly is not a luxury; it is a necessity. Ultra-thin borescopes are built to deliver sharp, high-resolution images even in confined and poorly lit spaces. LED illumination at the tip of the probe, combined with quality lenses and sensors, produces detailed visuals of corrosion, cracks, wear, and foreign objects.

Clear imaging helps technicians make confident decisions. Instead of guessing whether a surface imperfection is harmless or dangerous, they can zoom, capture still images, and record video for further analysis. This evidence can be shared with engineers, managers, or manufacturers to plan the safest and most cost-effective response.

Reduced Risk to Personnel

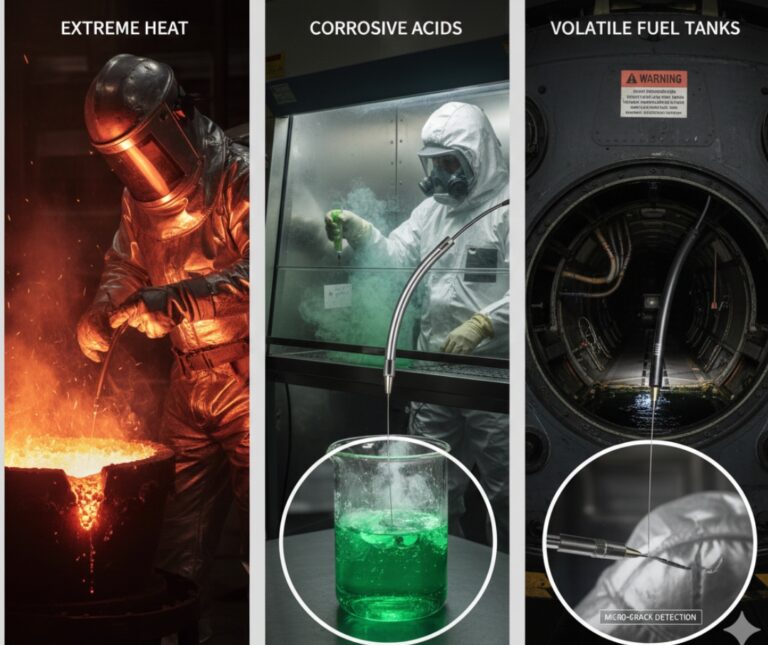

High-risk environments can involve extreme temperatures, pressure, toxic substances, or moving parts. Every time a human has to get close to these hazards, there is potential for injury. Ultra-thin borescopes help move the person farther from danger.

Because the probe is long and slim, the operator can stand at a safer distance while the camera travels inside the equipment. Visual inspection becomes a remote process rather than a hands-on one. In some settings, this can also reduce the need for confined space entries, scaffolding, or working at height, further lowering the risk profile of inspection tasks.

Durability Under Harsh Conditions

Equipment used in demanding environments must withstand more than everyday wear and tear. Ultra-thin borescopes are often engineered with robust insertion tubes, abrasion-resistant outer layers, and well-sealed connections. This construction helps protect internal wiring and optics from oil, moisture, dust, and mechanical stress.

Durability is crucial during repeated inspections. A borescope that fails in the middle of a job can delay critical maintenance and even force a shutdown. A well built ultra thin unit, designed specifically for industrial use, provides consistent performance and reliable results, inspection after inspection.

Choosing the Right Ultra Thin Borescope

Not all borescopes are suitable for high-risk applications. When selecting a tool, technicians consider probe diameter, flexibility, working length, articulation, image quality, and compatibility with recording devices. For technicians who need the smallest diameter borescope on the market, the benefits are even more apparent, since a slimmer probe can access openings that other instruments cannot reach.

Matching the borescope to the environment is just as important. Factors such as temperature limits, chemical exposure, and required ingress protection ratings all influence the final choice. A thoughtful selection process ensures that the device can operate safely and consistently where it is needed most.

Conclusion

Ultra-thin borescopes have become essential tools for inspecting high-risk environments. Their ability to access tight spaces without disassembly, deliver clear images, keep personnel at a safer distance, and withstand harsh conditions makes them ideal for industries where reliability and safety are top priorities. By investing in the right ultra-thin borescope, organizations gain better visibility into their critical systems, reduce unexpected failures, and protect both people and assets over the long term.