In many technical fields, seeing what is happening inside a machine or a tight structure is essential for accurate troubleshooting. Yet physically opening equipment can be time-consuming, expensive, and in some cases risky. This is why micro borescopes have become a valuable inspection tool for professionals who need precise visibility without taking anything apart. Compact, flexible, and engineered for clarity, these devices offer a practical solution when traditional disassembly is not possible. Their rise is also closely tied to the growing use of the Micro endoscope, which provides similar benefits for delicate inspections in confined areas.

A Noninvasive Way to Inspect Tight Spaces

Micro borescopes are designed to reach areas that would normally require significant dismantling. Their compact diameter allows technicians to guide the device through existing openings, such as small ports, vents, or natural gaps within machinery. This approach avoids interrupting operations or risking damage to components that are complex to remove or reinstall. In industries where equipment uptime is critical, the ability to inspect internal surfaces quickly adds operational value. Professionals in aviation, automotive repair, manufacturing, and energy systems all rely on these compact tools to make smarter decisions with minimal disruption.

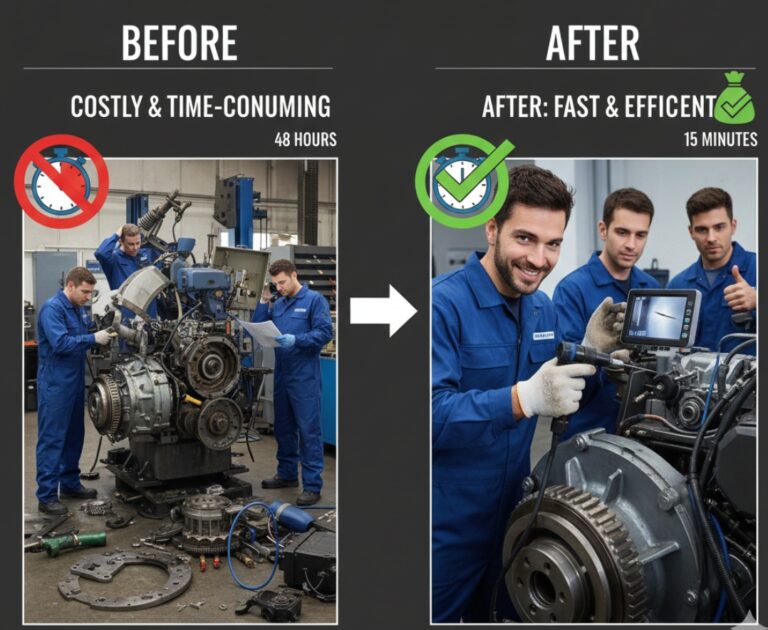

Reducing Labor and Downtime

Anytime a machine must be disassembled, it requires skilled labor, additional tools, and careful reassembly. Even minor disassembly procedures can lead to longer project timelines. Micro borescopes resolve these challenges by allowing technicians to perform diagnostic checks instantly. Instead of hours spent removing covers or structural components, professionals can insert the tool and get real-time visuals. This reduction in labor costs makes the inspection process more efficient. It also minimizes downtime, which is one of the most expensive aspects of maintenance in industrial environments.

Improving Accuracy With Clear Internal Imaging

A major advantage of micro borescopes is the clarity they deliver despite their small size. High-resolution imaging helps technicians identify cracks, corrosion, misalignment, or foreign objects inside the machinery. Since the device can be positioned precisely where issues are likely to develop, the assessment becomes more accurate. This ability to visually confirm internal conditions results in better maintenance decisions. Additionally, modern tools often include LED lighting and articulated tips, allowing users to navigate around bends and direct the camera exactly where it is needed. The Micro endoscope offers similar capabilities, helping specialists conduct delicate inspections where precision and care are essential.

Preventing Unnecessary Repairs and Extended Wear

Without visual confirmation, technicians may rely on assumptions that lead to unnecessary repairs or part replacements. Micro borescopes eliminate guesswork by allowing users to verify whether a component truly needs attention. This reduces material waste and prevents disruptions caused by avoidable repair work. More importantly, early detection of small issues helps extend the lifespan of equipment. Identifying wear patterns or hidden damage early allows for proactive maintenance, reducing the likelihood of larger, costlier failures. This preventive approach ultimately supports higher-quality performance across many industries.

Enhancing Safety for Technicians and Equipment

Disassembly often exposes workers to moving parts, pressurized areas, or sharp edges. Micro borescopes help reduce those hazards by allowing safe, external access to internal spaces. Technicians can inspect dangerous or hard-to-reach locations without direct contact. This tool also lowers the risk of damaging sensitive components during dismantling. When machines remain intact, the possibility of accidental misalignment or improper reassembly is greatly reduced, contributing to safer overall operations.

A Smarter Approach to Modern Maintenance

Micro borescopes reflect a shift toward more efficient and precise inspection methods. They provide access where traditional tools fall short, saving both time and money while delivering reliable results. These tools keep getting smaller, stronger, and better able to meet the needs of different industries as technology improves. Whether used in mechanical systems, electrical components, or delicate structures, their value lies in their ability to offer deep visibility without disruption. When disassembly isn’t an option, micro borescopes offer a smarter, safer, and more economical way to keep equipment functioning at its best.