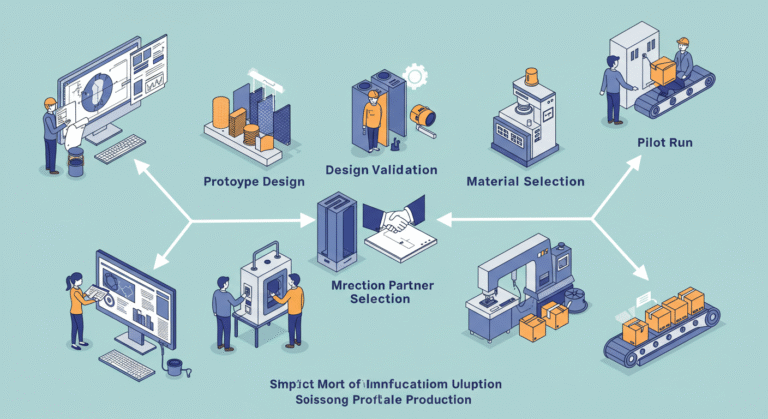

Making a new toy, gadget, or tool is so much fun! You start with a cool idea, maybe a drawing or a model called a prototype. But turning that model into something you can sell in stores takes a lot of careful steps. If you don’t plan well, you might have problems like broken parts, waiting too long, or things not working right. A clear and easy plan helps you make your product fast and keep it awesome.

This guide shows you simple steps to make your idea real. We’ll talk about checking your design to make sure it’s ready, picking the right stuff to make it, finding a helper to build it, making tools for it, and making lots of your product to sell. These steps help you avoid mistakes, keep your product great, and get it to stores quickly. Let’s dive in and learn how to make your idea come to life!

Validate Your Design for Manufacturability

Before you make tons of your product, you need to check if your idea is ready to be built in a factory. This is called Design for Manufacturability, or DFM for short. It means making your design easy to build so it doesn’t cost too much or break.

To do this, make your design super simple. Can you use fewer pieces? Maybe you can put some parts together so there are less steps to build it. A simple design is cheaper and faster to make. It also means your product won’t break as easily, which is great for everyone who buys it.

Try to use parts that are easy to find in stores. These are called standard components. They cost less money and you can get them quickly. If you use special parts that are hard to find, it might take a long time and cost more. Standard parts are like using regular LEGO bricks instead of rare ones.

Work with a grown-up engineer to check the sizes of your parts. Some sizes need to be exact, like the size of a wheel for a toy car. But other sizes can be a little different and still work fine. If you make all sizes super exact, it can cost a lot more money, and some parts might get thrown out because they don’t fit perfectly. Finding the right balance saves money and makes building easier.

Talking to someone who knows about making things is a big help. They can look at your design and tell you how to make it even better before you spend money on big machines. This step makes sure your product is ready to be made in a factory without any big problems.

Select the Right Materials

The stuff you used to make your first model might not work when you make lots of products. For example, maybe you used clay or soft plastic for your prototype. But for lots of products, you need materials that are strong, don’t cost too much, and are easy to find.

Think about if the material is strong enough. Can it handle heat, like being left in a hot car? Can it stay strong if it gets wet in the rain? Will it last a long time when people use your product every day? You want a material that makes your product tough and ready for real life.

Next, find a material that’s good but not too expensive. Fancy materials, like shiny metal, can cost a lot of money. Sometimes a strong plastic can do the same job but costs less. For example, a plastic toy car might be just as fun as a metal one but cheaper to make. Picking the right material saves money and keeps your product affordable for people to buy.

Make sure you can buy the material from many places. If you only get it from one store and they run out, you might have to wait a long time. That can mess up your plan to make and sell your product. Having more than one place to buy your material keeps things moving smoothly.

Picking the right material is super important. It makes sure your product is strong, affordable, and ready to be made without any delays.

Choose Your Manufacturing Partner

You need a grown-up helper, called a manufacturing partner, to build your product. They’re like the grown-up who helps you build a big LEGO set. They turn your idea into something real, so they need to be really good at their job and easy to talk to.

Look for someone who has made things like your product before. Maybe they’ve made toys, gadgets, or tools that are similar to yours. Ask them to show you examples or tell you about other projects they’ve done. This helps you know they can handle your idea.

A good partner checks every product to make sure it’s perfect. They have special ways to test things, like looking at each part closely to make sure it’s not broken. Ask if they have a certificate called ISO 9001. That’s like a gold star that shows they’re really good at keeping quality high.

You want a partner who listens to you and answers your questions. They should work with you to fix any problems. This is extra important if they do custom parts manufacturing, which means making special pieces just for your product. Not every factory does this, so find one that can make your unique parts.

Start talking to your partner early. Share your idea, but keep it a secret with a special paper called a non-disclosure agreement. This makes sure no one steals your idea. Your partner’s ideas can help make your product even better, so working together is key.

Plan for Production Tooling

Your first model might have been made with a 3D printer or a cutting machine. Those are great for one or two models, but to make lots of products, you need big tools, like molds or stamps. These tools make copies of your product fast. But they cost a lot of money and take time to make, so you need to plan carefully.

Work with your manufacturing partner to make the tools. They know how to design them so your product looks great and lasts a long time. For example, if you’re making a plastic toy, they might make a mold that shapes the plastic perfectly every time.

Making tools can take weeks or even months. If you’re making a toy for Christmas, you don’t want to be late! Add this time to your plan so you’re ready when the tools are done.

When the tools are ready, your partner will make a few products, called “first article” samples. Check these carefully. Are they the right size? Do they look good? Do they work like you wanted? If everything is perfect, you can tell your partner to start making more. If something’s wrong, you can fix it before making tons of products.

Good planning for tools makes sure your product is ready to go without any big delays.

Ramp Up Production Gradually

When your first samples look perfect, you might want to make thousands of products right away. But it’s smarter to start small with just a few. This is called a pilot production run. It’s like practicing before the big game.

Starting small lets you test how your product is made. Try putting it together to find any problems. Maybe the pieces don’t fit right, or the instructions are confusing. Fixing these now is easier than fixing thousands of products later.

Check that every product is just as good as the first ones, even when you make more. You want every toy, gadget, or tool to be perfect for the people who buy it.

Make sure your product is packed safely so it doesn’t break when it’s sent to stores. Test your shipping plan to make sure it gets to the stores on time. Maybe you need stronger boxes or a faster delivery truck.

After your small batch is perfect, you can make lots more. This careful start makes sure everything works great when you make thousands of products.

Pave Your Path to Market

Turning your idea into a real product is a huge deal! By using a structured and thoughtful process, like checking your design, picking good materials, finding a great partner, making the right tools, and starting production slowly, you make sure everything goes smoothly. This careful plan helps you avoid mistakes, save money, and make a product that’s just what you dreamed of. Now you’re ready to share your awesome creation with the world! Get ready to see your product in stores and make people happy with what you made.

Disclaimer: This article is for informational purposes only and does not copy any protected material. All content is original and meant to teach about moving from prototype to production. The author and publisher are not responsible for any actions taken based on this information. For professional advice, consult manufacturing experts. This content follows Google’s guidelines for original, high-quality content and avoids reproducing protected material. Contact the author with any concerns.

Jared H. Furness is a well-known sports analyst and writer. He is known for his skill in player stats in sports like football, basketball, and baseball. Jared has a sharp eye for detail and a passion for uncovering stories behind the numbers. He is known for writing detailed, SEO-friendly articles. They attract both fans and professionals.

His work often appears on major platforms. It offers detailed breakdowns of player performances, game highlights, and strategic insights. Jared makes complex statistics easy to understand and engaging. His articles, like the Boston College Eagles vs. UVA game analysis and the Arizona Diamondbacks vs. Miami Marlins match, show his talent for mixing data analysis with engaging stories.

Jared is known for producing human-written, plagiarism-free content. His pieces rank well on Google. This helps fans and analysts easily find his expert views on key matchups. Jared H. Furness raises the bar in sports stats journalism. He highlights Bobby Witt Jr.’s amazing plays and key moments in EuroLeague basketball.