Introduction

In today’s complex industrial and commercial environments, system outages and equipment failures can result in costly downtime and lost productivity. Investing in reliable infrastructure is crucial, and refurbished electrical components have emerged as a practical solution for organizations seeking to maintain robust operations without incurring high costs. Refurbished components deliver not just economic value but often improved performance, offering a compelling alternative to new parts. For companies looking to extend the life of their equipment while ensuring safety and efficiency, services like https://divergentalliance.com/electrical-equipment-testing-refurbishing/ provide trusted electrical testing and refurbishing solutions. Refurbishing electrical equipment involves restoring used parts to like-new function, ensuring they meet or even exceed original specifications. Businesses exploring these options can benefit from established best practices in the industry, including professional third-party electrical testing and refurbishing services.

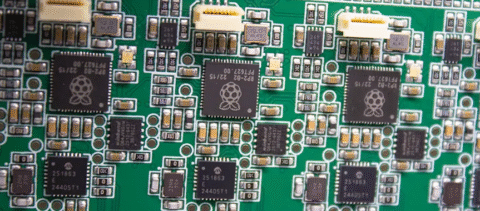

Understanding Refurbished Electrical Components

Refurbished electrical components encompass any previously used equipment that has undergone comprehensive cleaning, inspection, and restoration to ensure optimal performance. The refurbishment process typically involves disassembling the item, replacing or repairing defective or worn-out parts, reassembling it, and then conducting a rigorous battery of tests. Only after confirming compliance with performance benchmarks are these parts made available for reuse.

This method not only preserves the structural and functional integrity of equipment but also adheres to strict industry and safety protocols. By opting for professionally refurbished components, companies can keep vital systems operational, extend the lifespan of their assets, and avoid the pitfalls of unplanned outages.

Many industries, such as manufacturing, utilities, and commercial buildings, now integrate refurbished electrical components as a standard practice, recognizing their potential to deliver consistent, reliable service and a strong return on investment.

Cost-Effectiveness of Refurbished Components

Financial efficiency remains a leading motivator for businesses considering refurbished parts. On average, the refurbishment process can recover between 80% and 90% of the original value of the components, resulting in significant savings compared to purchasing new equipment. This economic benefit is particularly apparent in legacy systems or specialized machinery where new parts are either cost-prohibitive or no longer manufactured.

Aside from direct cost savings, refurbished components support business agility and flexibility. By reducing the investment required to maintain or restore operational equipment, companies can allocate resources toward critical upgrades, process improvements, or new projects. The competitive advantage of accessing high-quality, performance-validated parts quickly cannot be overstated in environments where uptime is paramount. As highlighted by UL Solutions, extending the lifespan of electronics through refurbishment strategies supports both fiscal and operational objectives.

Enhancing System Reliability

The reliability of a refurbished component is often comparable to, if not superior to, that of its brand-new counterpart. This outcome is achieved through exhaustive quality control and validation processes during refurbishment. Each component undergoes stress testing, burn-in cycles, and systematic evaluation to identify and eliminate latent defects—steps that exceed standard new-unit quality assurance. These measures are designed to ensure the unit performs reliably under actual deployment conditions, effectively reducing the likelihood of future faults.

Organizations adopting refurbished parts benefit from reduced rates of early-life failure, higher mean time between failures (MTBF), and consistent, predictable performance. When coupled with a robust preventive maintenance strategy, integrating refurbished components reinforces the overall dependability of critical systems.

Environmental Benefits

Switching to refurbished electrical parts is also a proactive way to mitigate environmental impact. Modern electronic waste presents a growing challenge, with billions of tons of e-waste produced globally each year. By refurbishing and reusing equipment, organizations play an active role in reducing landfill contributions and lessening the demand for raw materials necessary to produce new products.

The environmental impact of electronic manufacturing and disposal is well-documented. Companies embracing circular economy principles—where resources are kept in use for as long as possible—can align their sustainability initiatives with operational efficiency. This responsible approach helps businesses stay compliant with evolving regulations and appeals to environmentally conscious consumers and investors. According to UL Solutions, recycling and refurbishing electronics is central to tackling today’s e-waste crisis.

Challenges and Considerations

Despite the clear benefits, there are important considerations when choosing refurbished electrical parts. The availability of certain specialized or legacy components may be limited, particularly as original manufacturers discontinue their product lines. Compatibility must also be verified to avoid mismatches that could undermine system stability or void warranties. Furthermore, not all refurbishing providers adhere to established quality or safety guidelines, so vetting suppliers is critical.

Successful refurbishment strategies require diligent assessment of component status, clear sourcing protocols, and comprehensive testing both before and after installation. Partnering with reputable firms that offer transparent certification and documentation supports a smooth and trustworthy refurbishment program.

Implementing Refurbished Components in Your System

To maximize benefits and minimize risks, organizations should consider a structured approach when adopting refurbished electrical components:

- Assessment: Begin by thoroughly evaluating current systems to identify components that are candidates for refurbishment, analyzing age, criticality, and failure risk.

- Sourcing: Research and select suppliers who are industry-recognized, maintain clear refurbishment protocols, and provide complete testing records.

- Testing: Ensure every refurbished unit is subjected to exhaustive real-world validation and retains full compliance documentation before it’s reintroduced into service.

- Maintenance: Build ongoing monitoring and testing into maintenance schedules. Regularly inspect and test refurbished components to ensure optimal functioning and early detection of faults.

Developing clear processes for assessment, sourcing, and post-installation monitoring is crucial for ensuring system reliability when integrating refurbished components.

Final Thoughts

Embracing refurbished electrical components offers a prudent balance of reliability, economic efficiency, and environmental responsibility. With proper inspection, sourcing, and ongoing maintenance, organizations can extend the life of their assets, reduce operational costs, and support industry sustainability goals. The approach ensures continued high-quality performance of electrical systems while responding to modern demands for resource and cost efficiency.