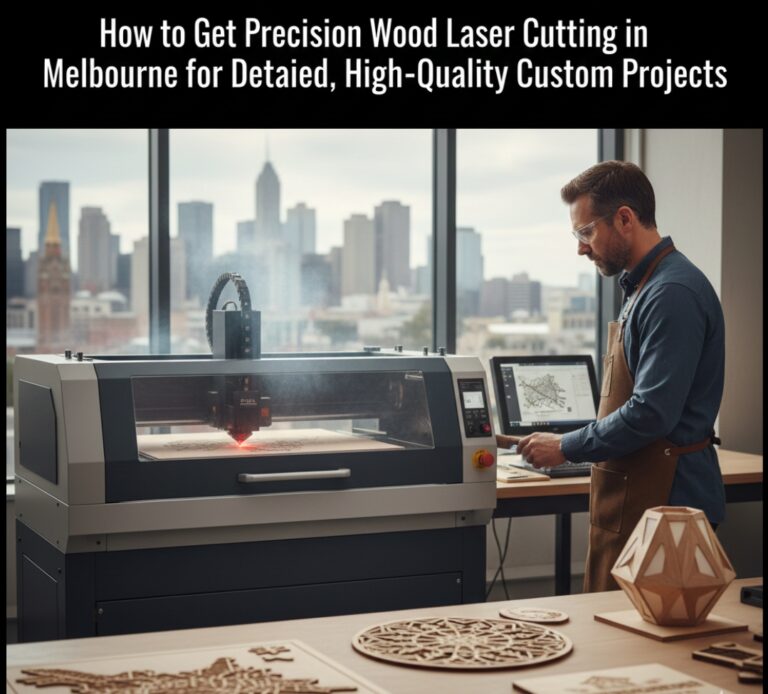

Custom woodwork projects demand accuracy that traditional cutting methods can’t reliably achieve. Whether you’re creating intricate signage, architectural models, decorative panels, or prototype designs, precision matters significantly. When you get precision wood laser cutting in Melbourne, you’re accessing CNC technology capable of cutting tolerances down to 0.1mm, something impossible with handsaws or even standard router work. Laser cutting uses concentrated light beams controlled by computer programming to vaporize wood along exact paths, creating clean edges without physical blade contact. This non-contact process eliminates issues like wood tear-out, blade deflection, or vibration marks that compromise manual cutting quality. Industrial data shows laser cutting reduces material waste by approximately 35% compared to conventional methods while increasing production speed by 60% for complex designs.

Understanding Laser Cutting Capabilities for Wood

Not all lasers handle wood equally well. CO2 lasers work best for wood materials, operating at 10.6 micrometer wavelength that wood absorbs efficiently. These machines cut through various wood types including plywood, MDF, balsa, basswood, and hardwoods up to about 12mm thickness in single passes, with multiple passes handling thicker stock.

Different woods produce different results. Maple and birch cut cleanly with minimal charring, while resinous woods like pine create more smoke and edge darkening. Plywood quality matters significantly because adhesives affect cutting, low-quality plywoods with formaldehyde glues produce toxic fumes and inconsistent edges. When sourcing laser cutting services, ask specifically about their experience with your chosen material. A shop familiar with your wood type can adjust power, speed, and frequency settings for optimal results.

Finding Quality Laser Cutting Services in Melbourne

Melbourne has numerous laser cutting providers but capability varies widely. Look for shops with industrial-grade machines rather than hobbyist equipment. Industrial lasers offer larger cutting beds (typically 1300mm x 900mm or bigger), higher wattage (80 to 150 watts for wood), and better ventilation systems managing smoke and fumes.

Check provider portfolios showing completed wood projects similar to yours. A company specializing in acrylic cutting might struggle with wood-specific challenges like grain direction, moisture content effects, or managing char marks. Read reviews mentioning turnaround times, customer service responsiveness, and whether finished pieces matched design specifications. Get samples if possible, examining edge quality, corner precision, and overall finish before committing to large orders.

Preparing Files for Laser Cutting Success

File preparation makes or breaks laser cutting results. Most services accept vector formats like AI, DXF, or SVG since lasers follow vector paths. Raster images won’t work, they need conversion to vectors first. Your design should specify cut lines (typically red in design convention) versus engraving areas (usually black).

Line thickness matters, use hairline or 0.001mm strokes for cut paths since thicker lines can confuse machine interpretation. Avoid overlapping lines or duplicate paths because lasers will trace each line, potentially burning through wood or creating gaps. Check that all paths are closed properly, open shapes won’t cut out completely. Most providers offer file review services catching issues before cutting starts, which saves material costs and frustration.

Cost Factors and Timeline Expectations

Laser cutting pricing depends on multiple variables including material type, cutting time (longer, more complex paths cost more), machine operation time, and material sourcing. Most Melbourne services charge by machine minute, typically ranging from $2 to $5 per minute depending on machine specifications and project complexity.

Expect quotes within 24 to 48 hours for standard projects, though complex designs might need longer estimation. Production timelines vary, simple projects might complete same-day while intricate work or large quantities could take a week or more. Rush services usually cost 50 to 100% premiums. For repeated production runs, many shops offer discounted rates since setup only happens once, making laser cutting increasingly economical for medium to large batch productions.