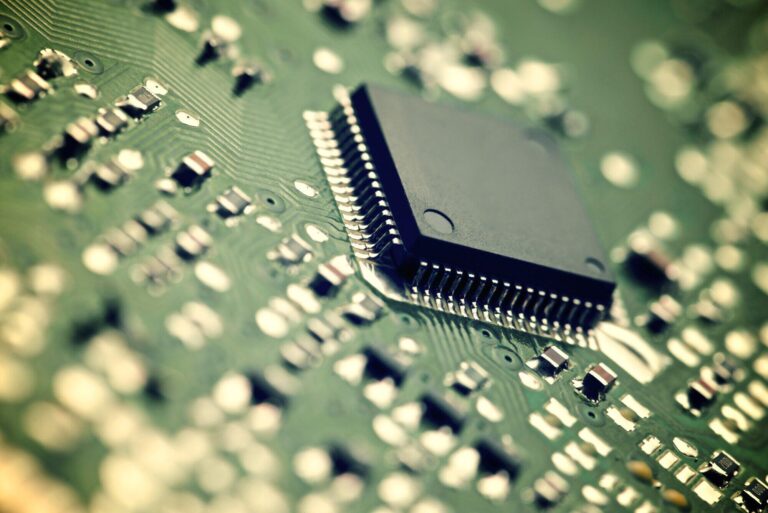

Semiconductor manufacturing may seem hard, but the idea behind it is simple. Every chip starts with a wafer, and the quality of that wafer affects everything that comes after it. When you choose high-quality wafers, you give your entire process a strong start.

Keep reading to learn how better wafers can help your line run more smoothly, increase your output, and help your business stay ahead in a fast-moving world.

Why Wafers Matter in Chip Manufacturing

Wafers are the base for every semiconductor device, so the quality of the wafer guides the quality of the finished chip. A clean, smooth wafer helps tools work better because there are fewer tiny flaws.

When machines move smoothly, the steps in the process stay on track. A strong base also helps each layer stay even and stable, making the final chip more reliable.

Improving Process Control

High-quality wafers help bring order to the whole line. When wafers have even thickness and flat surfaces, machines can place layers and patterns more accurately.

This helps prevent errors that would normally happen during coating or etching. With fewer problems along the way, production becomes easier to plan and easier to manage.

Boosting Yield Rates

Yield rate is the percentage of chips that turn out working and ready to sell. When wafers have fewer defects, more chips pass the final check. This helps reduce waste and saves money on materials. A higher yield also helps companies fill orders on time and keep customers satisfied.

Supporting Advanced Technology

New technology needs stronger wafers because modern chips are tiny and complex. These chips have small lines and tight layers that must be placed with great care. High-quality wafers can handle these small details without bending or breaking. This helps companies create advanced devices without losing quality.

Reducing Downtime and Repair

Poor-quality wafers can slow down machines and even damage tools. Scratches, cracks, or rough spots force workers to stop the line to fix the issue. Every pause reduces output and adds cost. Using better wafers helps prevent these interruptions, keeps the tools safer, and keeps production moving forward.

Better Heat Control

Heat plays a big role in making chips because wafers go through many heating steps. If a wafer bends or cracks from heat, the whole chip can fail. Strong wafers stay steady under high temperatures, which helps each layer bond the right way. This gives the final device more strength and better performance.

Cleaner Surfaces for Better Performance

Tiny bits of dust or small marks can ruin a chip before it is even built. High-quality wafers start out cleaner, and this helps keep the process clean. The smooth surface helps layers stick better and helps machines place patterns more accurately. This leads to chips that work better and last longer.

Supporting Modern Lithography Needs

Modern lithography uses special light to create tiny circuits on the wafer. This light needs a surface that is smooth and free of defects. When wafers are stable, the light can form the shapes with great accuracy. This allows the circuits to stay sharp, clean, and ready for high-speed tasks.

Meeting Industry Standards

As chips get smaller and faster, the rules for making wafers get stricter. High-quality wafers help companies meet these rules and stay trusted in the industry. Meeting standards also shows customers that the company is reliable. Strong wafers help businesses compete in a market where quality matters.

Making Future Growth Easier

When companies choose better wafers, they prepare for growth. Strong wafers support new tools, new designs, and new methods. They also help teams build chips for fields like electric cars, medical tools, and AI systems. A better base makes it easier to expand into new areas without major delays.

Adding Flexibility to Production

Good wafers give companies more choices in what they can create. These wafers can handle different chip layouts, sizes, and layers. This helps companies shift production when market needs change. Flexibility also helps reduce risk because the company can react quickly to new trends or demands.

Consistency You Can Trust

Consistency is key in chipmaking. When every wafer is the same high quality, machines stay aligned and results stay even. This gives companies a steady level of quality that customers can depend on. From layer to layer and chip to chip, strong wafers help keep the line uniform.

A Smart Investment for Long-Term Success

High-quality wafers may seem more expensive at first, but they save money over time. They help prevent waste, protect equipment, and keep machines running longer. They also improve output, which helps raise profit. Over many cycles, better wafers bring more value than cheaper, weaker ones.

Support for Complex Chip Structures

Some chips have many layers and tiny spaces between them. These designs are hard to build and need wafers that are strong and steady. High-quality wafers can handle the extra steps without breaking. They give engineers the chance to build new and complex designs with confidence.

Tools and Materials Working Together

In chipmaking, tools and materials must work like a team. When wafers are smooth and even, tools can place layers with few errors. This reduces friction and keeps the line steady. With strong materials and good tools, the whole process becomes smoother and more efficient.

Improved Precision for Better Results

Many tools in this field are delicate and must work with exact detail. These tools need a clean and level surface to create tiny shapes on the chip. High-quality wafers give them the base they need. This leads to chips that work faster, run cooler, and last longer.

A Key Part of Modern Manufacturing

Strong wafers help every step in chipmaking. They help control heat, guide patterns, and support advanced methods. Chips cannot reach their full potential without a strong base. Even the best machine cannot fix a problem caused by a weak wafer.

The Importance of Specialized Options

Some projects need special wafers made for tight patterns or new research. These wafers allow for new ideas and new designs to be tested. They help engineers push technology forward with patterned silicon wafers.

Build a Stronger Future with High-Quality Wafers

High-quality wafers can help you make better chips by improving accuracy, reducing waste, and creating a smoother flow in production. With better materials at the start, each step that follows becomes easier and more reliable. This leads to stronger results, better products, and more success in a fast-moving industry.

Explore your wafer options today and take the first step toward a stronger and more advanced future.

Check the rest of our site for more!